Humble 3D Printed Product Designs that can effortlessly change the world! - Yanko Design

3D printing has evolved and how! Ever since its inception, 3D printing has excited the states with the tremendous possibilities it offers u.s.a.. Granted, we spent plenty of time 3D printing our models for fun, designers now have used this innovative tool to create technologies that can really save the earth. From canteen-caps that tin can quench the stranded tourist'southward thirst to complete structures beingness 3D printed to offer a condom refuge when in need, there is a solution here that is effectively basis-breaking and has been manufactured by the apprehensive 3D printing technology!

Designed to magically 'turn air into water', the Limbe past Fabien Roy is a new sort of dehumidifier that works without electricity, giving its user access to drinking water throughout the twenty-four hours. Its unique leaf-inspired blueprint harks dorsum to how h2o aerosol condense on the surface of leaves, while its 3D printed intricate PET construction helps guide those water aerosol down the 'veins of the leaf' into Limbe'southward central axis which collects the water in your regular plastic drinking bottle.

An unlikely yet enthusiastic new member of the salve-the-oceans movement is the Swedish carmaker Volvo. The Living Seawall is comprised of hexagonal tessellated tiles that sport a complex, interwoven structure that mimics the roots of a mangrove forest. The concrete tiles are starting time cast using a 3D printed mold and and so mounted on man-made seawalls across Sydney, promoting the growth of microorganisms (they accept to the tiles as they would to mangrove roots) that constantly feed on ocean water, purifying information technology of toxins, chemicals, and even minute particulate matter.

3D printed from sand, the 'Spirula' speakers by the Czech company Deeptime seem similar they're from another planet together! Silica sand was the material of pick. The porous and brittle 3D printed sand cones were treated with Deeptime'south special hardener, resulting in an airtight conch vanquish. Shaped after the spiral-shaped cochlea in the man ear and inspired by the deepwater squid Spirula, these speakers are anything just ordinary.

The Desert Pavilion was created to be a communal oasis of heritage and micro-ecology. When y'all look at the renders, the structure is a blend of local Bedouin architecture with space-age technology. The design team has envisioned an innovative use of 3D printed panels by deploying them onto a CNC bent steel pipage system. To simulate a holistic tent-similar construction, the squad used a hybrid of 3D printed polymer shells on 3D printed concrete topography with the 'Mesh Relaxation' parametric strategy.

Created as a collaboration between Formula i, Designer Parfums, and Ross Lovegrove Studio, the bottles are F1's debut in the fragrance market place, and help capture an olfactory experience that most die-hard F1 fans will relate to… the smells of burnt rubber, brake oil, and wet asphalt. The perfumes don't literally smell of called-for rubber, only evoke a similar representation. Playing with ingredients like black pepper, musks, bergamot, leather, among others, the fragrances, bachelor in a serial of 5 bottles, capture the adrenaline rush that is Formula i.

Apart from the electronics, and the rider, every ounce of the BigRep Nera is 3D printed. From the handlebars to the torso, to the seat, pause, and even the tires, the Nera is an absolutely stunning feat of design and engineering science melded together to show how far additive 3D printing has come. The eastward-bike'southward body comes with an edgy, chiseled pattern that gives it character and forcefulness, and even includes a flexible bumper underneath the seat to absorb shock. Fifty-fifty the airless tires are made from 3D printing, with a lattice structure that gives it both strength and flexibility, allowing it to mimic natural safety tires.

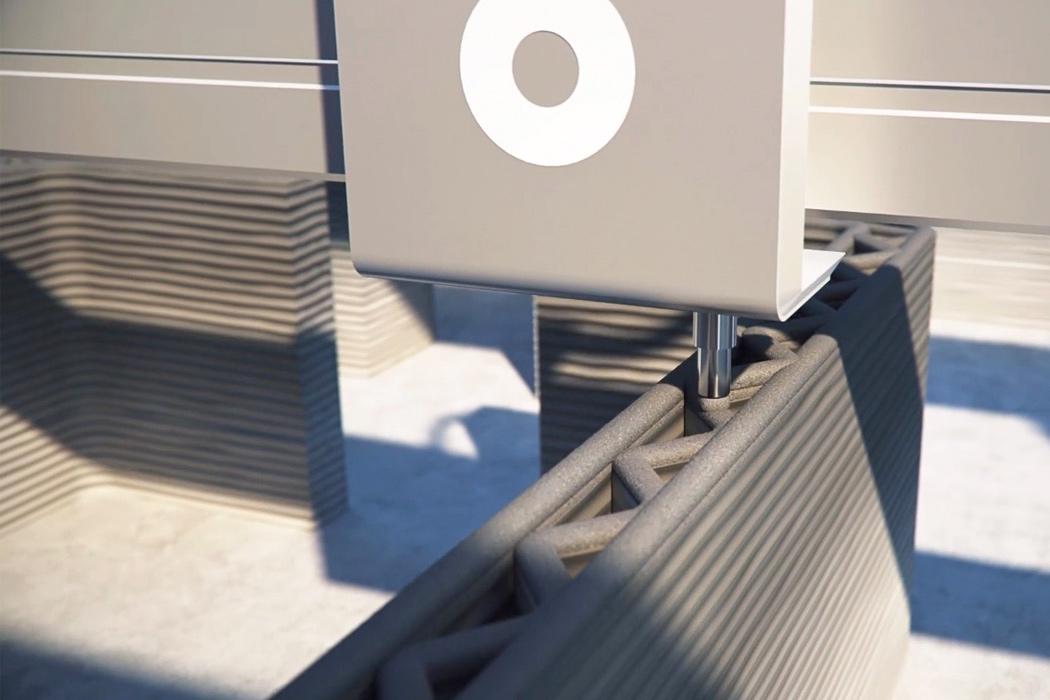

Yves Béhar and his studio fuseproject worked with tech company ICON to create the world's first 3D-printed neighborhood in Tabasco, Southern United mexican states. A lively 3D-printed neighborhood of fifty 500-square-foot, unmarried-story houses for the poorest communities who are always the last to benefit from innovation and engineering. ICON issued its Vulcan II printer for the purpose at paw. In 24 hours a base cement domicile with walls is built, with roofs, doors, and windows added afterwards. Vulcan Two's functionality is foolproof against rainfall, power shortages and almost dilemmas in rural areas. The slanted roof provides protection against intense rainfall. And the stiff base of operations and walls volition support the construction against seismic action.

Designed to prove off their advanced titanium condiment press techniques (and too their engineering prowess), they designed the globe's first guitar that can't exist smashed. Literally. After creating a design that they accounted was the strongest guitar ever made (they ran their own crash-test simulations also), Sandvik 3D printed the guitar out of titanium dust using an additive manufacturing process chosen Direct Metallic Laser Sintering.

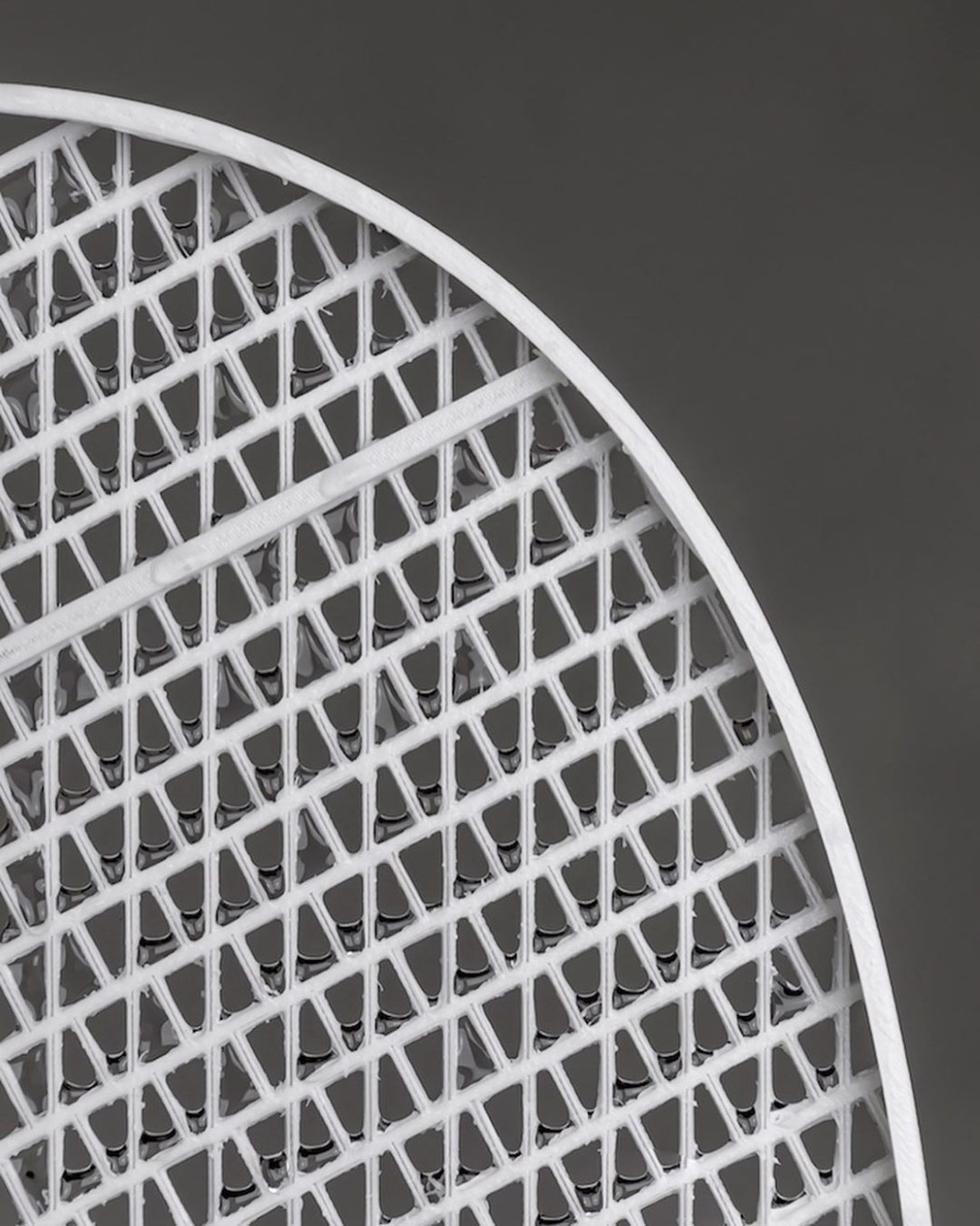

SHOELAB, created by Martin Sallieres has been developing a 3D weaving technique, creating shoes from one cloth. By tweaking the properties of this cloth, the designer can play with density, flexibility, thickness. Very much like nature does. For instance, the structure of a tree is very dissimilar between the twigs and trunk and is still fabricated from one material. The created mesh is a total polyurethane shoe inspired by the weaving techniques of spiders, with a constant back and forth movement along the shoe cast.

Although 3D press has merely picked up, in that location are quite a few 3D printed bicycle designs out there. None, however, are made of steel. None of them too expect every bit beautiful as the Arc Wheel. Created by the students at TU Delft, based in The netherlands, the Arc bike has an intricately detailed cycle frame made to look like it was woven, rather than printed.

Source: https://www.yankodesign.com/2020/03/18/humble-3d-printed-product-designs-that-can-effortlessly-change-the-world/

0 Response to "Humble 3D Printed Product Designs that can effortlessly change the world! - Yanko Design"

Post a Comment